When building high-temperature structures, it is worth taking care of building materials such as refractory concrete. Only this type of product, qualifies for use in the creation of heating equipment.

Refractory concrete is a high-quality building material with special properties. It is distinguished by its exceptional resistance to very high temperatures. It can be used as a lining product for boilers or furnaces. In addition, it is used in the nozzles of oil and gas burners. Ceramic furnaces are built with it and panels for waste incinerators are lined with it. High-temperature mortar has a low iron content in its composition. It is worth remembering that this product needs to be preheated in order to evaporate the residual moisture in it. This process is necessary because its absence can result in cracking of the concrete, exposed rapidly to too high a temperature.

Refractory concrete – a specialised building material

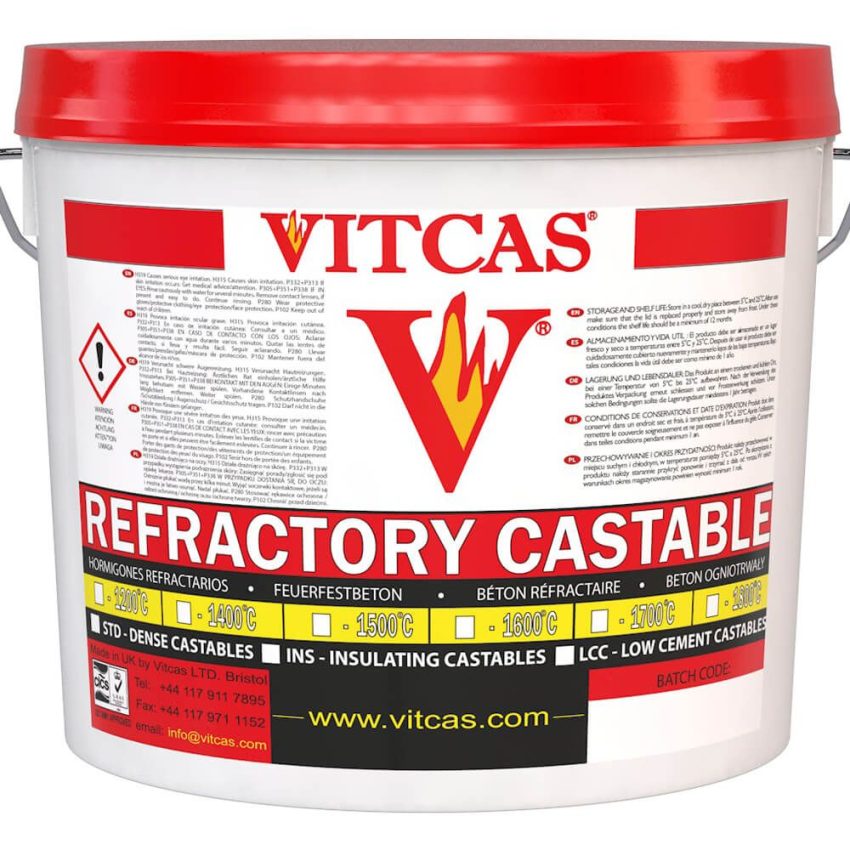

The refractory concrete proposed by the Vitcas shop can be used as a supplementary material when repairing furnace or boiler linings, as well as fireplaces. It can be used both indoors and outdoors. It withstands temperatures of up to 1,600 degrees Celsius. It is sold as a powder to be mixed with water. It is very effective and sets within 12h, at an ambient temperature of 20 degrees Celsius. High-temperature mortar is a product that is very popular with Vitcas shop customers. It has been thoroughly tested by them and has received masses of good feedback.

Read also:

Fire-resistant tile adhesive – reliable at high temperatures

Heat-resistant glazing adhesive – excellent protection against heat

Refractory concrete will prove itself as a building material for special applications. It is characterised by its ability to withstand extreme temperatures, which is useful during construction and maintenance, for example of various types of heating structures.