When building a cooker or making repairs to a boiler, it is worth thinking about the right material for lining them. This is why many people wonder how to make fireproof concrete? This product can be found in the Vitcas shop range.

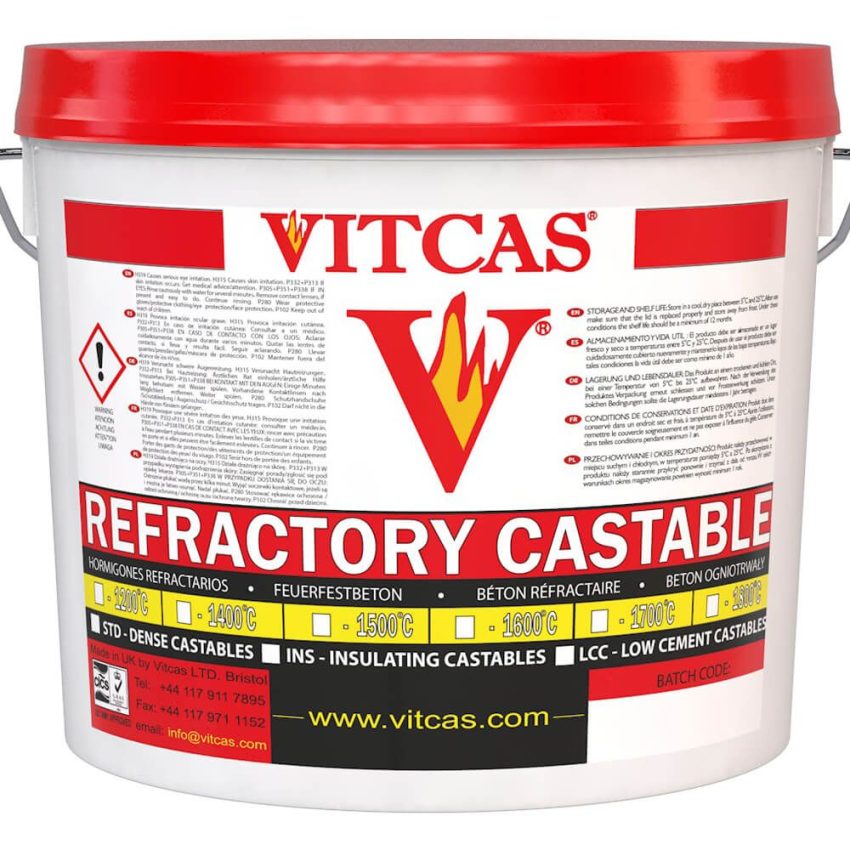

Replacing the lining of a cooker or boiler, or repairing it, requires a material such as refractory concrete. This type of product can be ordered by selecting it from the range of the renowned Vitcas shop. This product can be used to cover surfaces exposed to very high temperatures, for example in the nozzles of gas or oil burners. It can also be applied to the joints of ceramics and glass, where a low iron content is important. This product is sold in the Vitcas shop as a powder to be mixed with water. It is packaged in economical-to-use 25 kg buckets.

How to make refractory concrete? – process of preparing the product for use

When buying powdered concrete, many people have no knowledge of how to make refractory concrete. According to the manufacturer’s recommendations, mix the powder with the correct amount of cold water. It is important that both the bucket, the tools and the water itself are clean. Refractory concrete is sold in durable buckets and can also be mixed in these. It is a good idea to remember to heat the concrete after it has been applied to the desired surface, thus allowing the excess water in it to dry. Skipping this step may result in cracks in the newly formed lining surface. Therefore, after the concrete has been applied, a 12h setting time is required, at 20°C.

Read also:

Stable adhesive for tiles, high-temperature adhesive mortar

Specialised refractory concrete for furnaces and boilers

Incandescent concrete is a material used to repair linings in chimneys, furnaces or boilers. It is designed to operate at very high temperatures and is therefore distinguished by its special properties.